Our products

Field bus module

From I/O modules and autonomous sections to complete plug & play flex conveyors.

Sensors

Decentralised data acquisition and evaluation with direct connection to your IIoT platform.

Industrial Switches

Reliable acquisition of all relevant measurement data, especially in the field and industrial environment.

WLAN-Module

Fast and simple crosslinking of systems and field comp-onents using radio links.

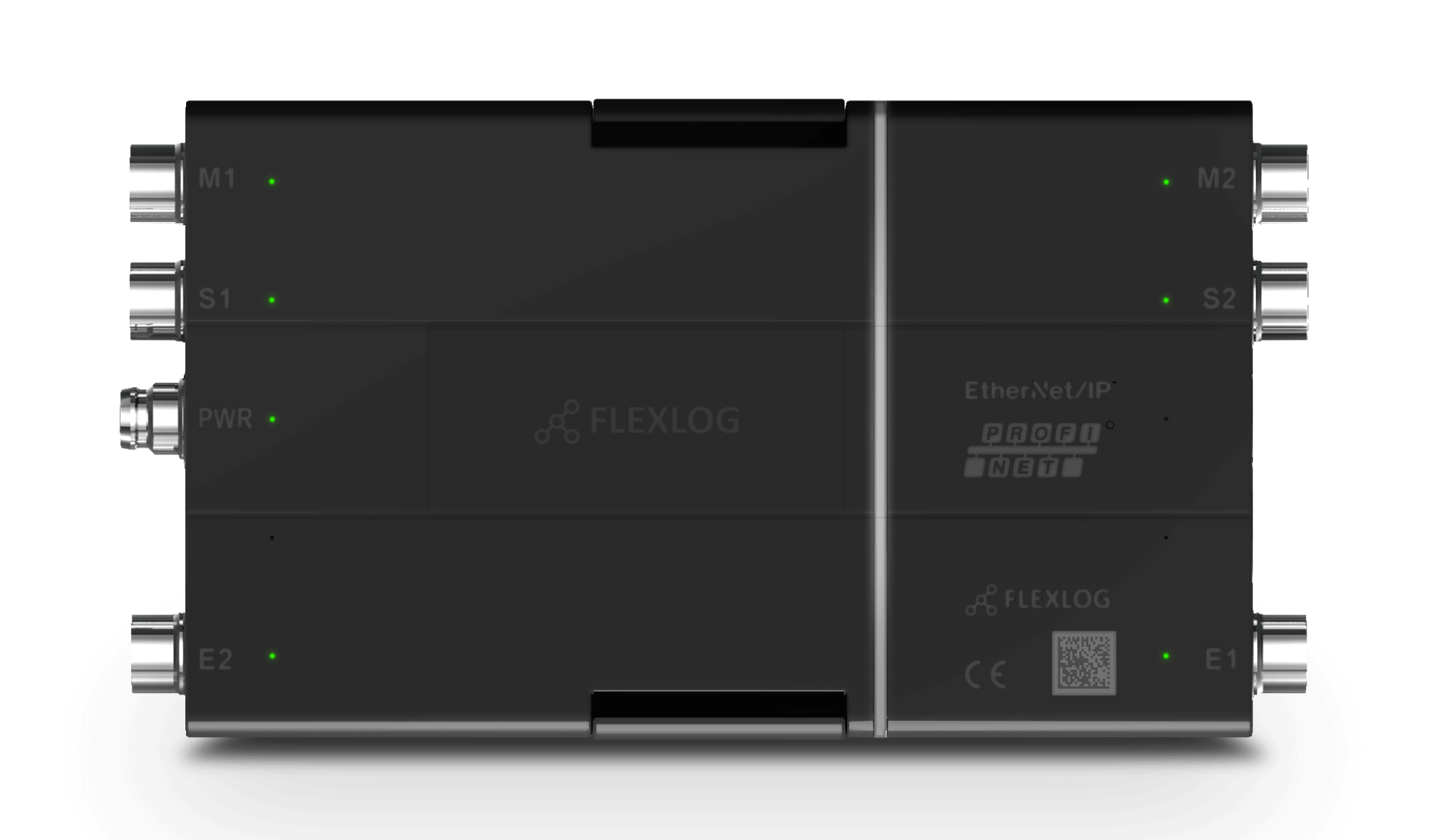

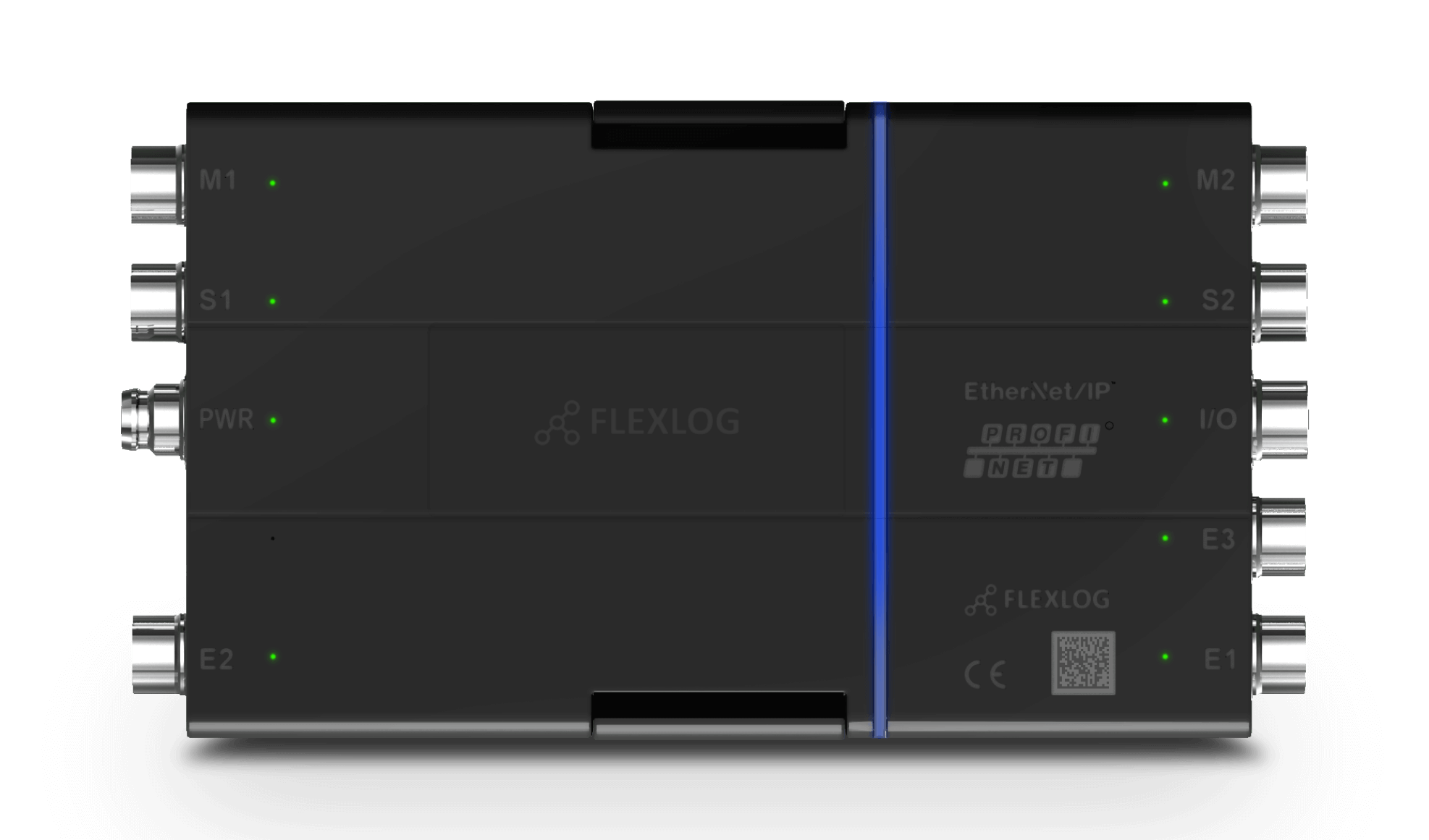

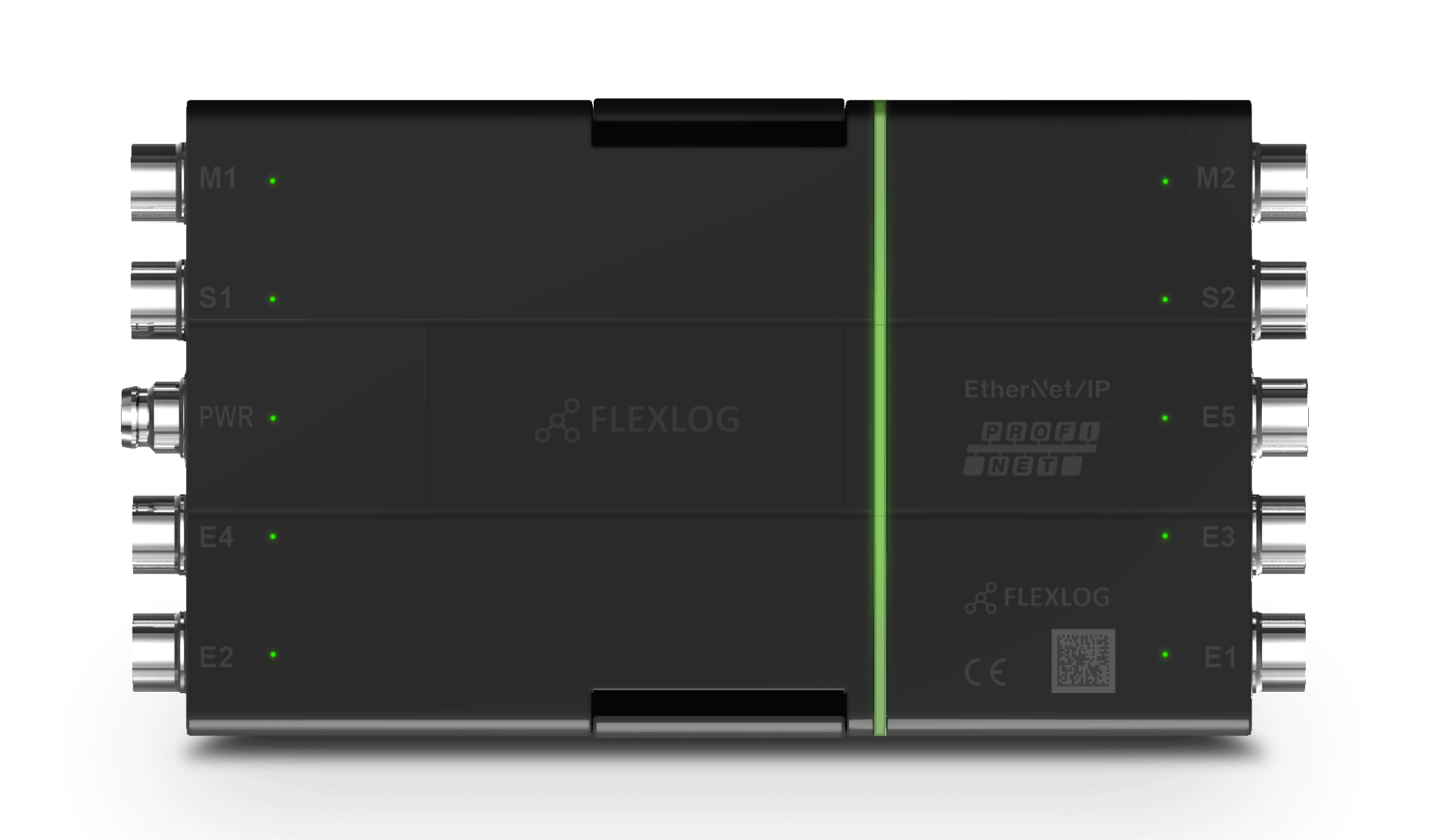

flexbox

Our ProfiNet and EtherNet/IP-capable flexboxes offer everything from simple I/O modules to plug & play-capable decentralized controls and decentralized material flow control system

HORIZON

The IIoT platform for your intralogistics system - a complete overview from detailed areas to the location overview, visualization of your plant, intelligent systems for process optimization and support for your entire team.

More

Your future is our future!

We are looking for talents in all areas! With us you will have modernly equipped workplaces in a quiet atmosphere, an innovative working environment, flat hierarchies and likeable colleagues. You want to revolutionize the industry? Then become part of our team!

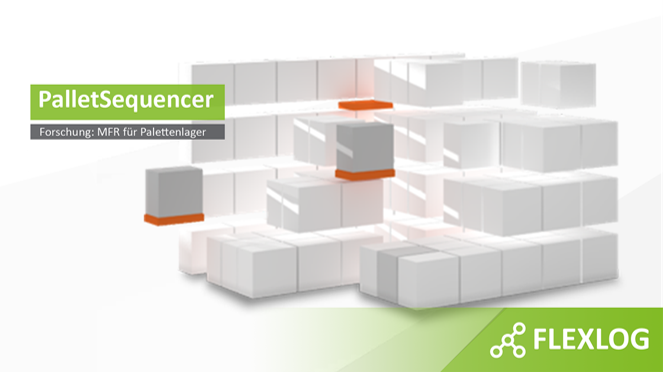

MoreExciting news! We recently had the pleasure of interviewing one of our developers about the successful completion of our PalletSequencer research project. Here is a short summary of the interview!

A warm invitation to LogiMAT! Europe's largest international trade fair for intralogistics solutions will take place from March 19 - 21 in Stuttgart. We look forward to welcoming you in hall 5 at our stand C75!

Great news: We are exhibiting at the SPS trade fair in Nuremberg for the first time! Visit us at our booth 512 in hall 10!