Conveyor system controlled on a decentralized basis

Each individual module equipped with black , orange or green. These flexboxes can communicate with each other and thus control the entire system. Starting with the control of the sensors and actuators via the control of subsystems up to complex material flow computers – but in a decentralized manner – the flexboxes take over all necessary control tasks across all levels.

Even if one module should fail: Individual elements can be replaced quickly and easily at any time. The single point of failure of a classic central material flow computer is compensated by the decentralized approach. This means that your conveyor system is protected against large-area failures and can also be flexibly extended.

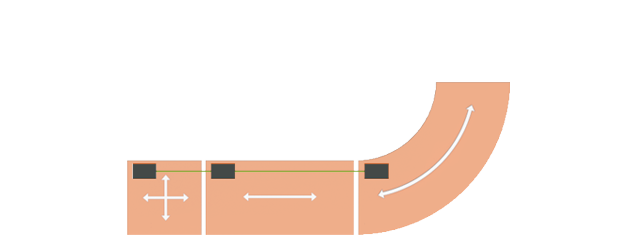

Simple and flexible

The FlexConveyor can be easily adapted to your requirements. Our software automatically detects the routing paths and finds alternative routes if problems occur. For you, this means: No deadlocks, no collisions and no programming effort.

Plug & Play

The decentralized control automatically recognizes new topologies, allowing you to make adjustments at any time. For example, if one module fails, it can be replaced at short notice without adversely affecting the other elements. After the faulty module has been removed, the new exchange module can easily be inserted into the conveyor system via plug & play.

Short commissioning times

If you currently need two weeks to commission a plant, we can do it in two days.

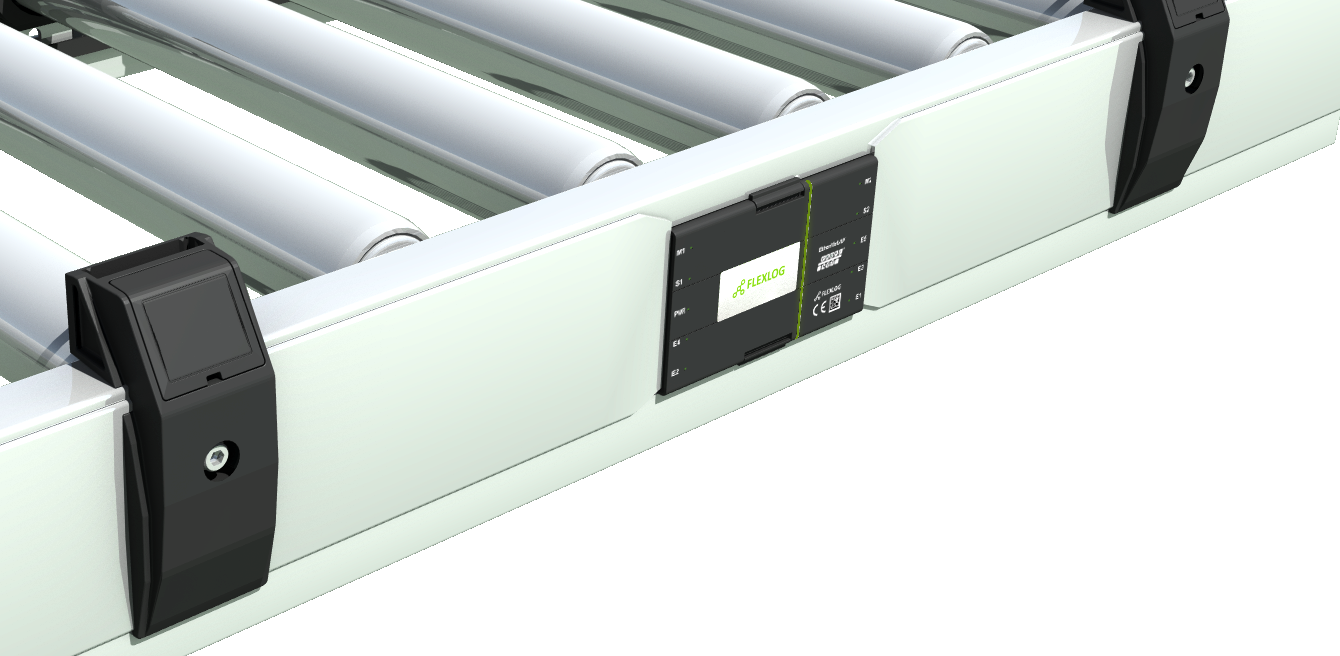

Control via our flexbox

Each module is equipped with one of our flexboxes. Using the different variants, we can assemble a FlexConveyor that precisely corresponds to the requirements of your conveyor system, from controlling simple logics to PLCs and all the way to fully flexible decentralized control.

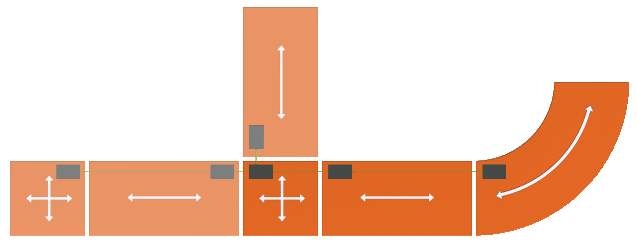

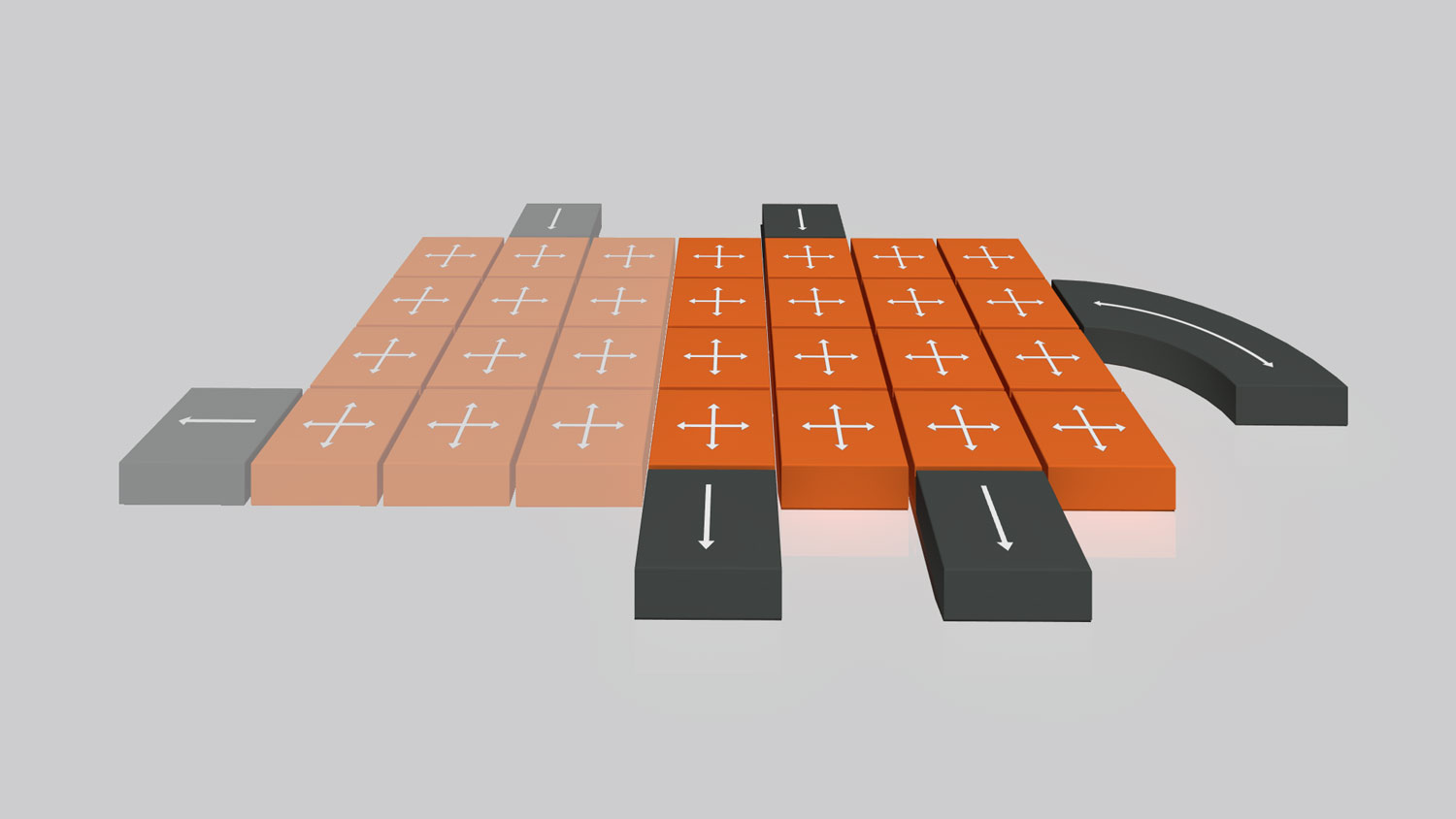

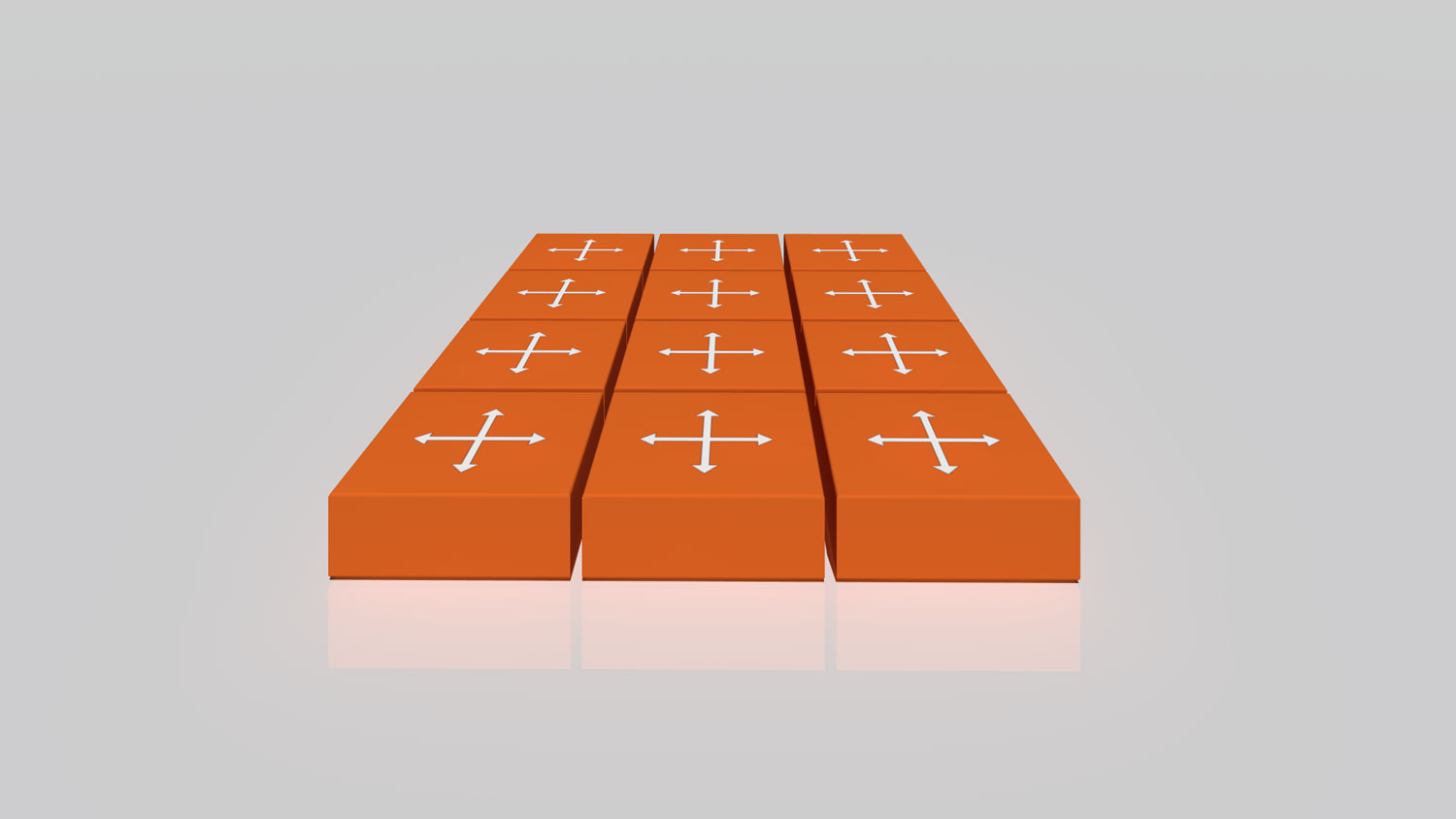

Completely decentrally controlled sorter

GridSorter was developed on the basis of our FlexTechnology as part of a research project at the Institute of Conveying Technology and Logistics Systems (IFL) at the Karlsruhe Institute of Technology (KIT). Under the direction of Prof. Dr.(Eng) Kai Furmans, new algorithms have been developed that enable a fully decentrally controlled sorter for the first time. The modular design and flexibility of the system opens up completely new possibilities for sorters in addition to the classical fields of application.

Benefits and functions

Flexible layout adjustments

The GridSorter can be flexibly adapted to your needs. The layout and infeed/outfeed can be changed as required.

Space-saving

The GridSorter has a compact design. With an output of 3,000 to 12,000 units per hour, the GridSorter has an advantageous ratio of throughput and space requirement. Depending on the layout, the modules of the sorter have different utilization rates. The software recognizes the utilization of individual modules and can thus, for example, use little-utilized modules to buffer conveyed goods.

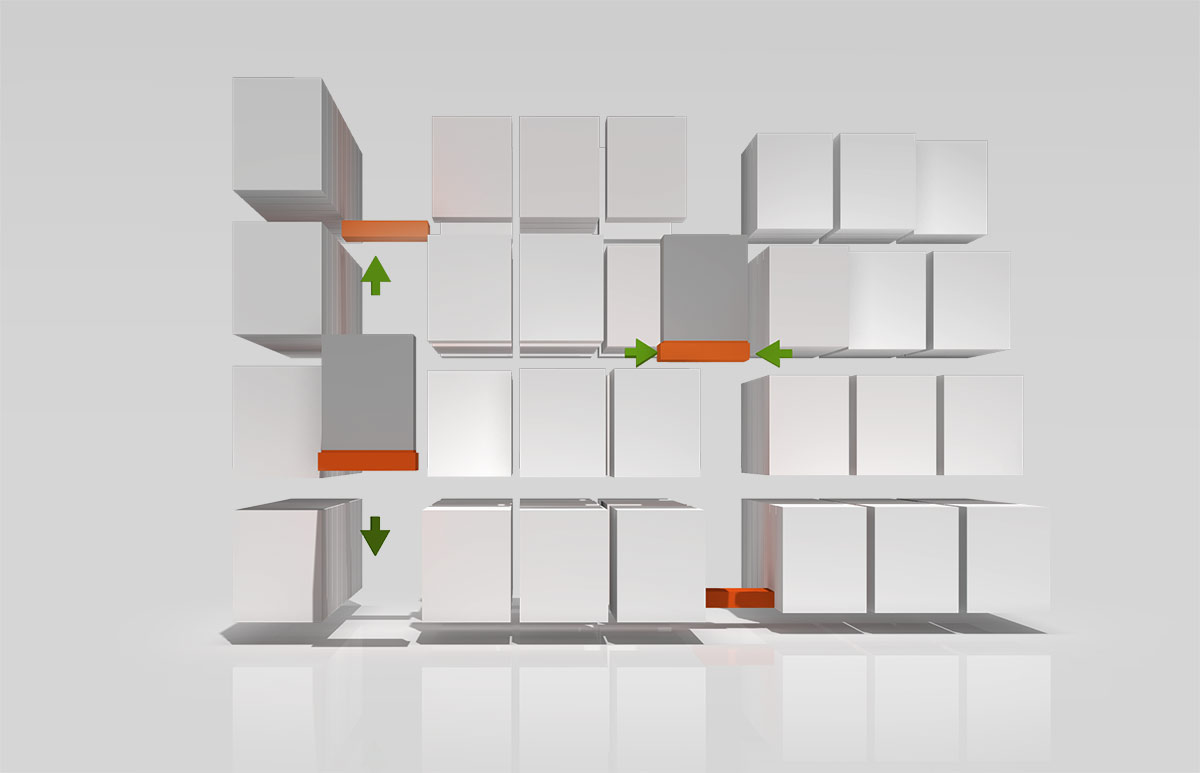

3D shuttle control

No matter how many shuttles in the warehouse, the flexlog 3D shuttle control routes the shuttles reliably, free of live- and deadlock and unidirectionally through the warehouse – even with high demands on throughput, layout or flexibility.