Modular, customizable, scalable

Do you only need certain functions or do you want the complete package? You have the choice!

Assemble your platform from the following modular components.

Questions about individual modules?

Would you like more information or do you need advice?

We're here to help!

individually adaptable

Safe, faultless and com-

plete transfer of your

data and high flexibility

in use of hardware.

HORIZON enables both the connection of new systems,

as also existing systems from every manufacturer.

on any end device

Intuitive navigation through responsive design. Multi

touch-enabled and end

devices independent.

Self-contained, simple administration because of easy connection to your internally existing user management.

systems and processes

All processes, workflows, employees and objects are well-arranged on one platform - everything at a glance.

through encryption

Functional separation of front and back end, as well as data exchange via exclusively encoded connections.

Visualization

Would you like an overview of your plant and would like to map complex systems or processes?

With the system visualization, you not only receive information on individual material flows, systems, actuators or sensors, but also an overview of the location of your entire system.

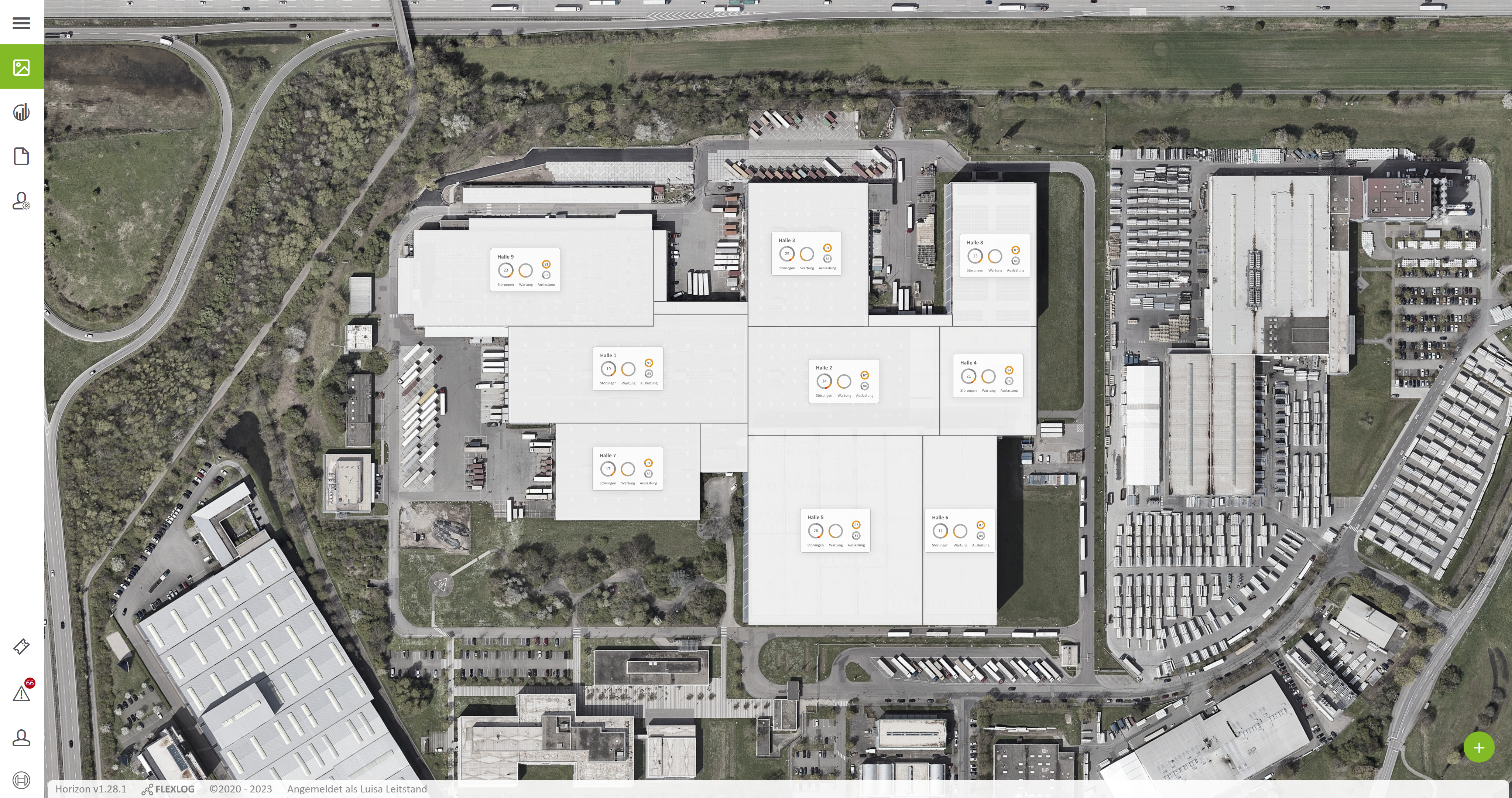

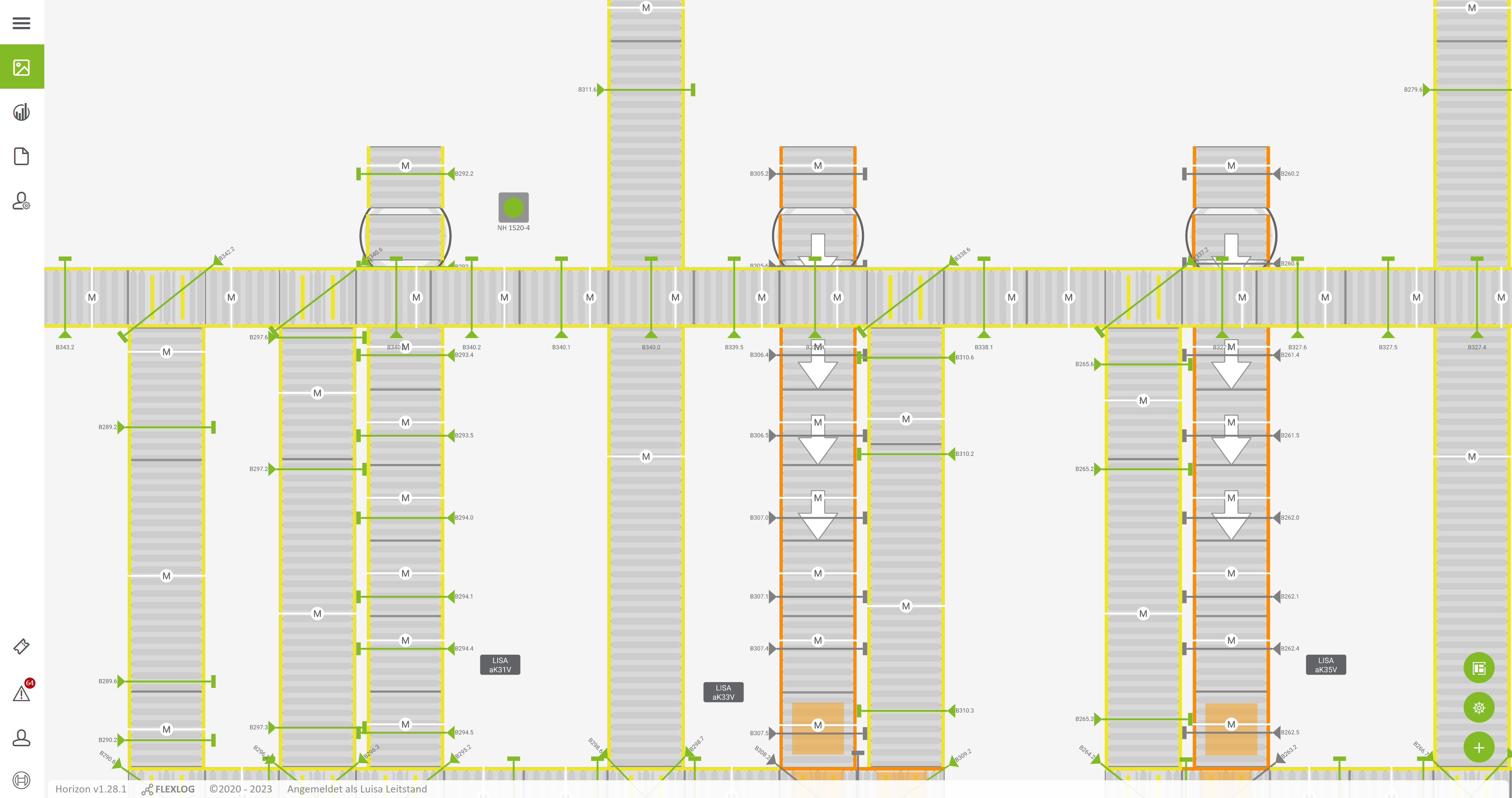

Your entire system at a glance

Complete location overview with practical status reports for each individual hall. Exact tracking including traceability and history through documentation of your material flow.

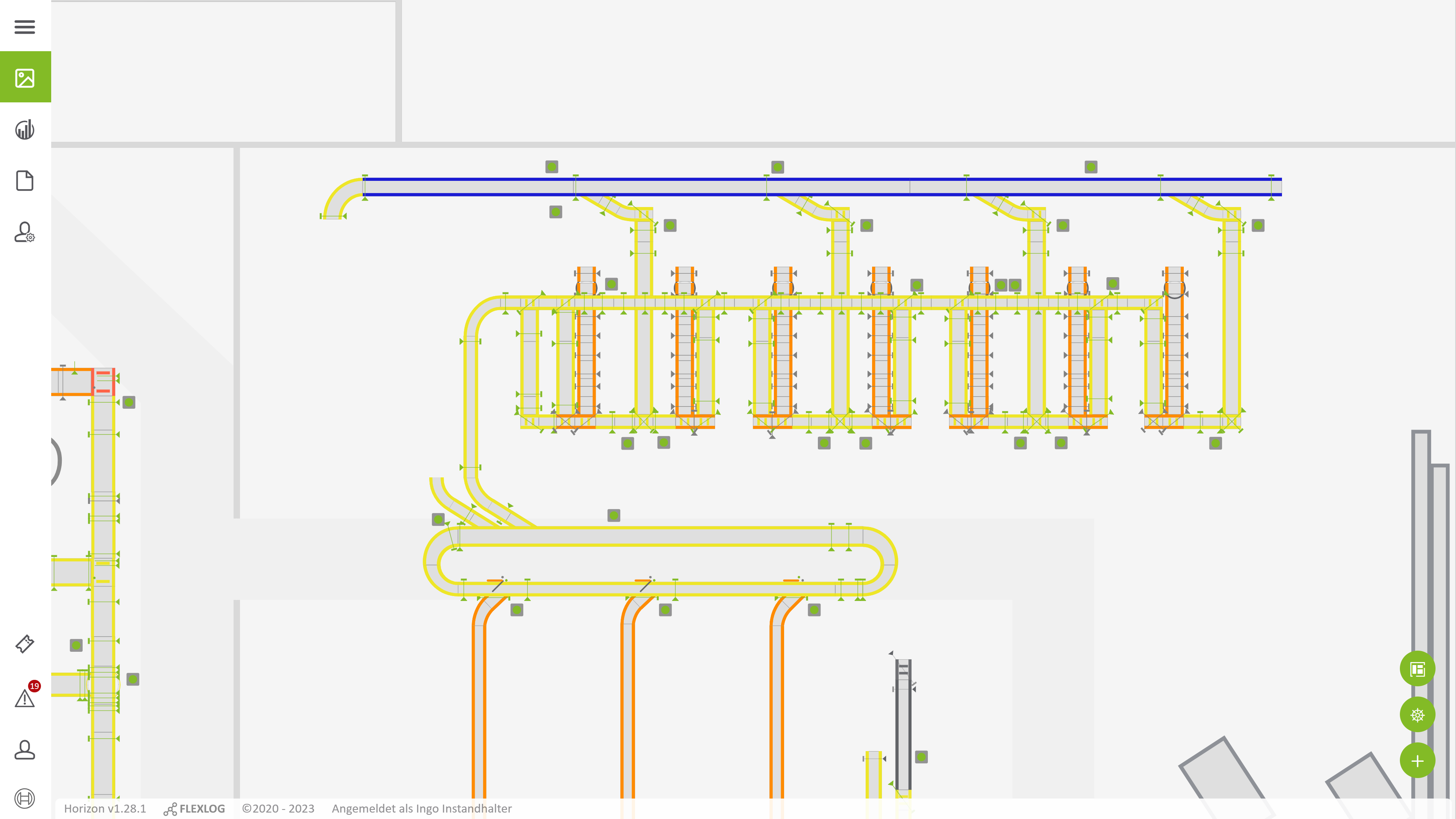

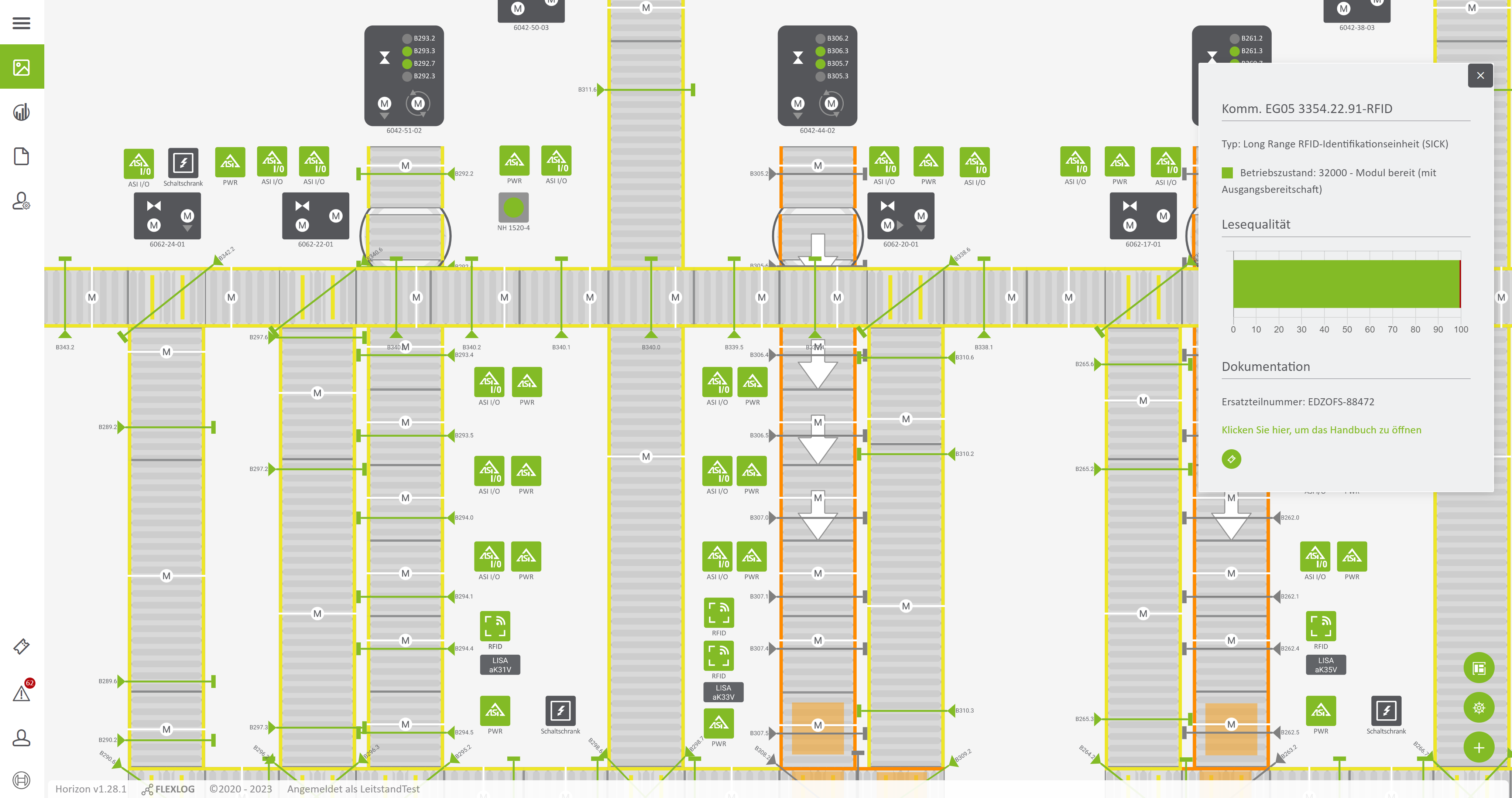

Maximum system overview down to the last detail

Comprehensive information about individual workstations, components and states, as well as detailed information about individual components and states up to the sensor-actuator level.

Cost reduction through time savings

The ability to generate, review and delete transport orders via the system visualization supports you in your planning process and saves time and personnel.

Easy change between manual and automatic

Intervene in your material flow and simply switch between manual, semi- and automatic operation. Individual motors can be switched on and off manually.

Material Flow Controller

Do you need a reliable control for complex processes such as the connection of an AGV fleet,

a warehouse pre-zone conveyor technology or a shuttle control? Our centrally controlled material flow controller

optimizes your throughput, routes bidirectionally and prevents dead and lifelocks.

Handling complex processes

Automated, comprehensive control of the entire logistics process across a wide variety of intralogistics systems. All system states and individual modules can be traced in real time.

Efficient routing algorithms

Fast response times and high flexibility in the routing of materials, as well as the prevention of disruptions through a patented algorithm with guaranteed freedom from deadlock and lifelock.

Wide range of developed modules

Individually configurable, fully developed modules can be quickly and easily integrated into an existing logistics system. No unnecessary costs for functions that are not required.

Planning security through scalability

Thanks to the distributed computing capacities and the modular structure, an individual yet scalable solution is made possible. Error states are recognized immediately by the replay function.

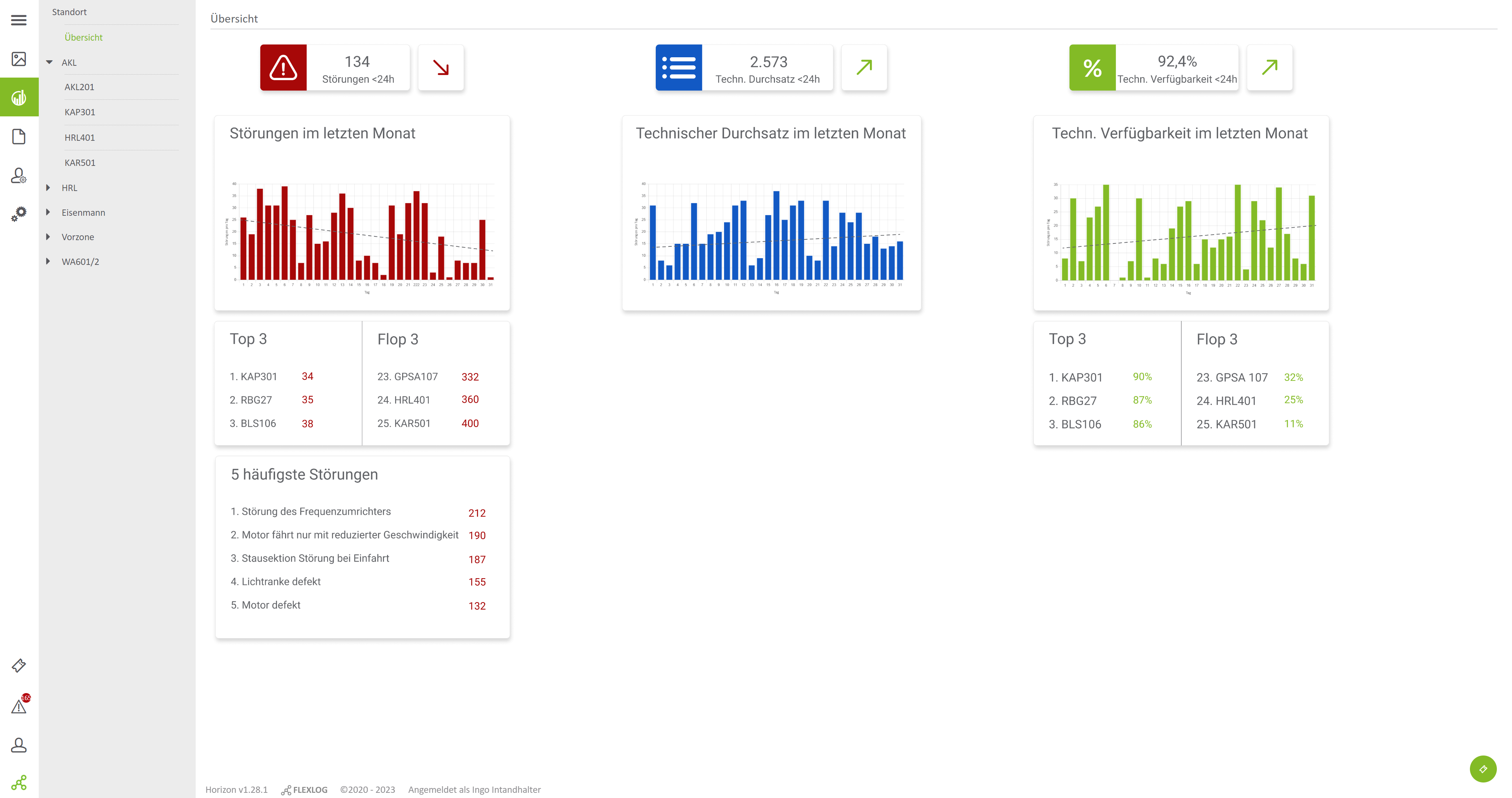

Analysis

Are you not satisfied with superficial information? Would you like detailed analyzes

and evaluations of the condition of your system? Then we recommend our process analysis, which uses statistical

evaluations to show you the comfort status of your system.

Optimization of all intralogistics processes

The process analysis generates detailed statistics that show the optimization potential of your system. Among other things, statistical key figures such as throughput, utilization or availability.

Identification of weak points and disturbance sources

You receive utilization overviews and malfunction heatmaps as a graphic representation of the identified weaknesses and bottlenecks so that you can counteract them as quickly as possible.

Monitoring trends

Based on the evaluation of long-term developments, our Analysis provides feedback on new work processes, as well as comprehensive trend analyzes and efficiency evaluations.

Recommendations for action to optimize efficiency

Our process analysis monitors the status of your individual system components and downtimes, evaluates their data in real time and can thus evaluate the upstream and downstream processes.

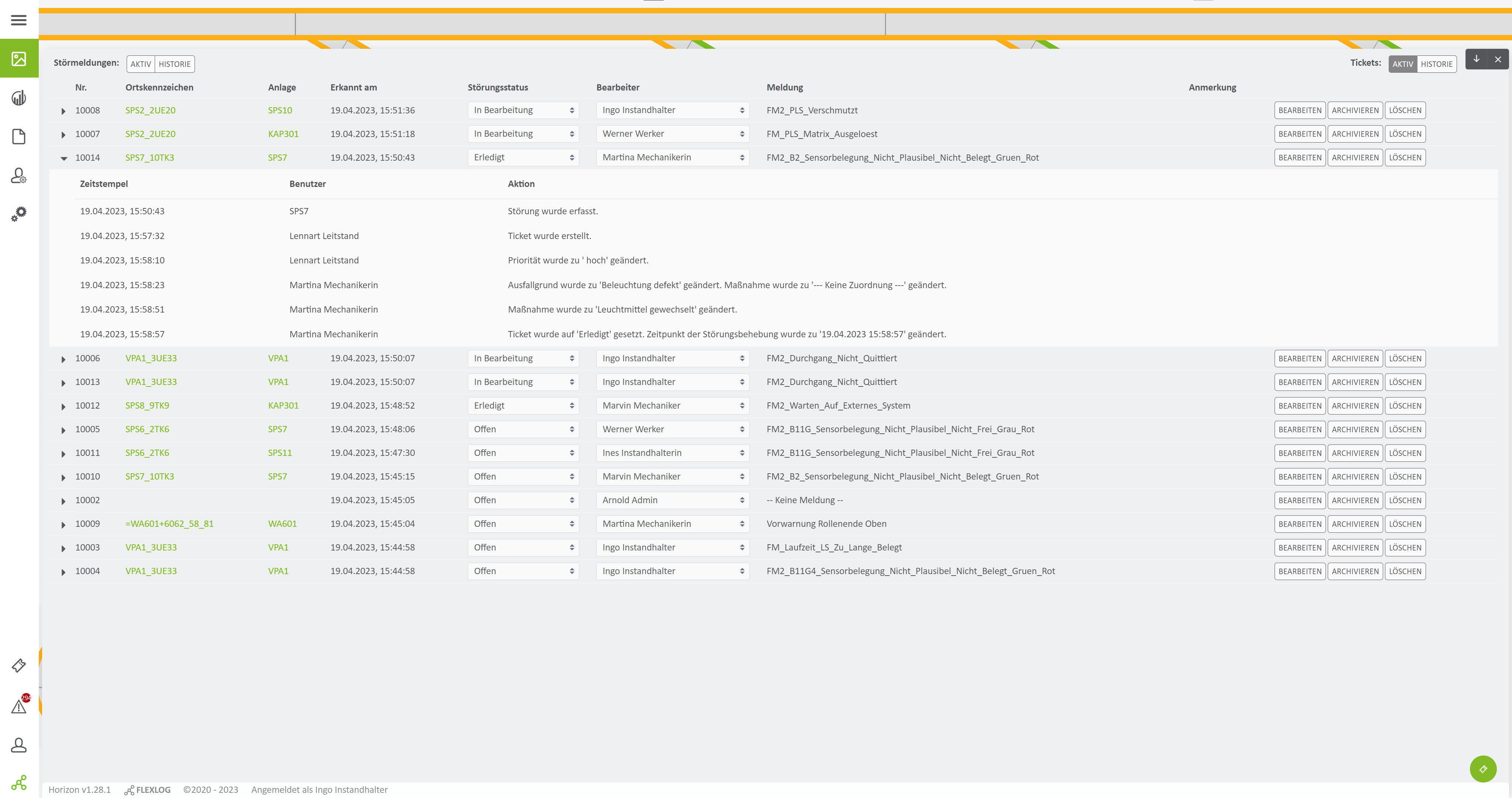

Ticketing

Technical disruptions impede your material flow and lead to downtimes?

A quick detection and elimination of sources of interference without time-consuming troubleshooting

is therefore your top priority when operating your system?

Recording of all technical malfunctions

Any form of technical malfunctions and process malfunctions are recorded and reported in text form or by graphical display, if desired. Sources of interference of any kind are recognized immediately.

Integrated ticket system

Fort he targeted rectification of faults you can choose to manually create tickets or to integrate the ticket creation as an automated process and thus relieve your maintenance team.

Traceability through history

The entire history is recorded so that you can view and track all malfunctions and ticket distributions. If necessary, additional information on the source of interference can be displayed.

Practical push notifications

In order to handling the tickets, our ticket system enables a person-related assignment to the responsible persons by e-mail or a practical push notification directly on mobile phone.

Maintenance

Don't worry about planning complex maintenance processes anymore!

Our maintenance system relieves you of maintenance management and informs you in good time

if maintenance is required for systems or system parts.

Consistently documentation

Guarantee of maximum availability through automatically generated maintenance reports, which make the work of your maintenance team easier. Avoidance of documentation errors.

Control of all maintenance measures

Reduction of failures and consequential damage through preventive maintenance. Areas or components to be maintained are reported and can be linked to a spare parts management system.

Extension of the durability of your system

Integrate the maintenance tasks into your planning process condition or time-based and save time in the implementation of your preventive and predictive maintenance tasks.

Optimal capacity utilization of your employees

Create absolute planning reliability for production processes by assigning maintenance tasks individually to responsible persons and guaranteeing rapid implementation.

Questions about HORIZON?