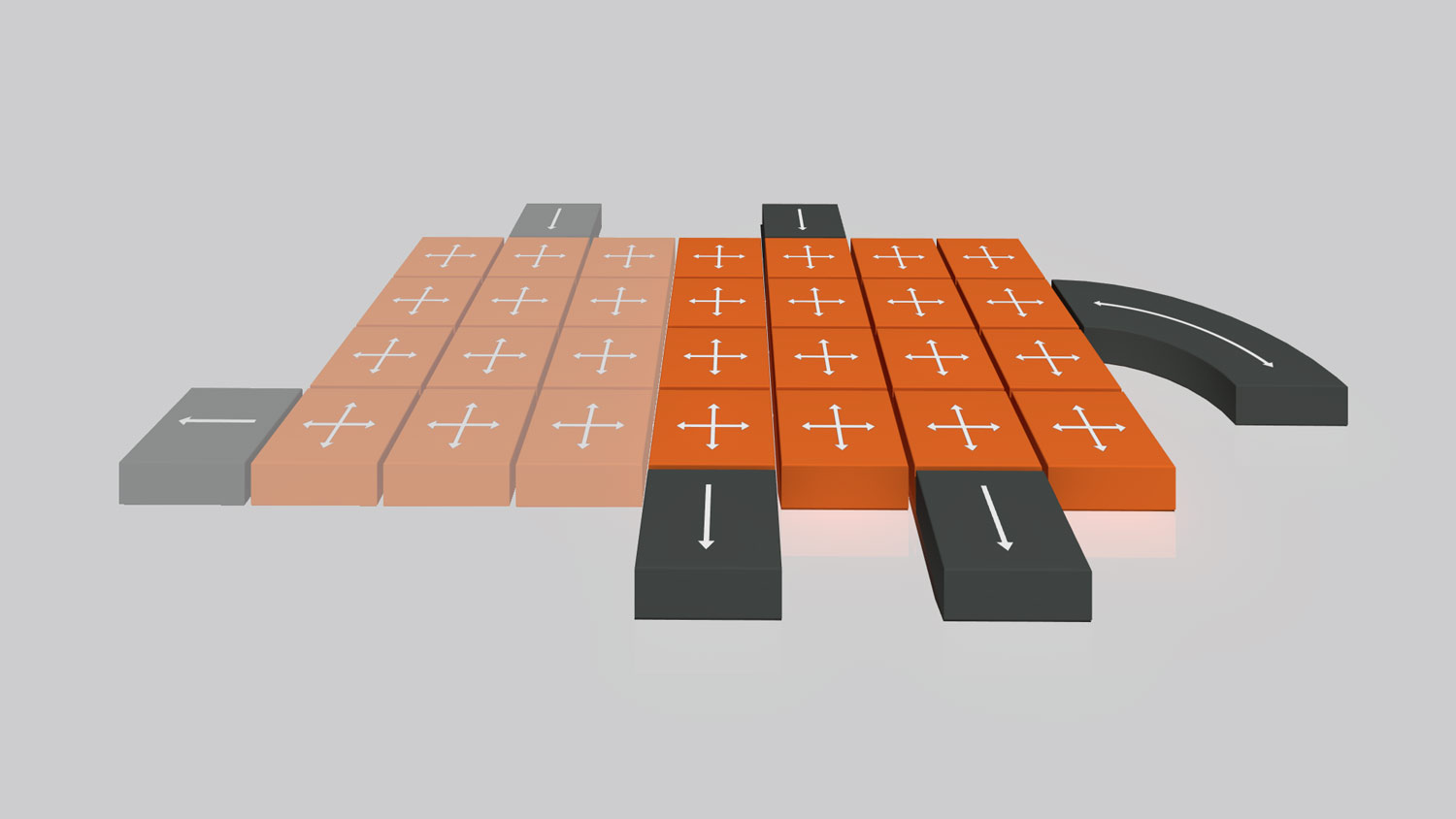

Die dezentral gesteuerte Förderanlage

Jedes einzelne Modul ist je nach Anforderungen mit black , orange, blue oder green ausgestattet. Diese Flexboxen können miteinander kommunizieren und steuern so Ihre gesamte Anlage. Begonnen mit der Ansteuerung ihrer Sensoren und Aktoren über die Steuerung von Teilanlagen bis hin zum komplexen Materialflussrechner – jedoch dezentral – übernehmen die flexboxen über alle Schichten hinweg alle notwendigen Steuerungsaufgaben.

Auch wenn mal ein Modul ausfallen sollte: Einzelne Elemente können jederzeit schnell und einfach ausgetauscht werden. Der single point of failure eines klassischen zentralen Materialflussrechners wird durch den dezentralen Ansatz kompensiert. Damit ist Ihre Förderanlage sowohl vor großflächigen Ausfällen gesichert als auch flexibel erweiterbar.

Einfach und Flexibel

Der Flexförderer kann unkompliziert an Ihre Anforderungen angepasst werden. Unsere Software erkennt selbständig die Routingwege und findet bei eventuell auftretenden Problemen automatisch Alternativrouten. Das bedeutet für Sie: Keine Deadlocks, keine Kollisionen und kein Programmieraufwand.

Plug & Play

Die dezentrale Steuerung erkennt automatisch neue Topologien, wodurch Sie Anpassungen jederzeit vornehmen können. Fällt beispielsweise ein Modul aus, kann es kurzfristig ersetzt werden, ohne dass die anderen Elemente nachteilig beeinflusst werden. Nachdem das fehlerhafte Modul entfernt wurde, kann das neue Austauschmodul ganz einfach per Plug&Play in das Fördersystem eingefügt werden.

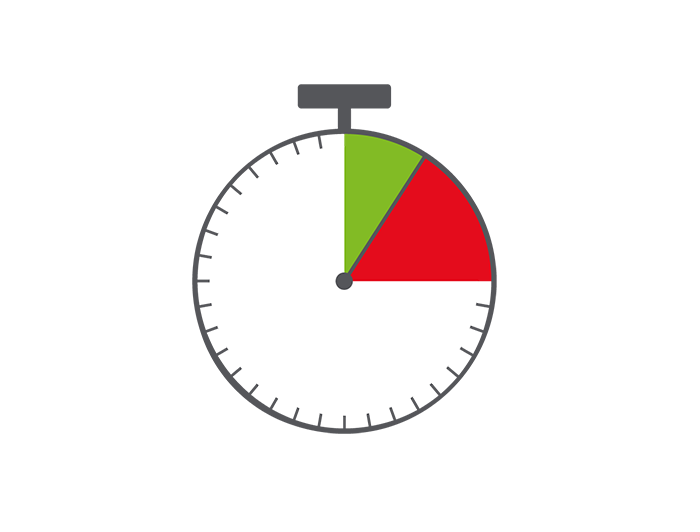

Kurze Inbetriebnahmezeiten

Brauchen Sie heute für die Inbetriebnahme einer Anlage zwei Wochen erledigen wir es in zwei Tagen.

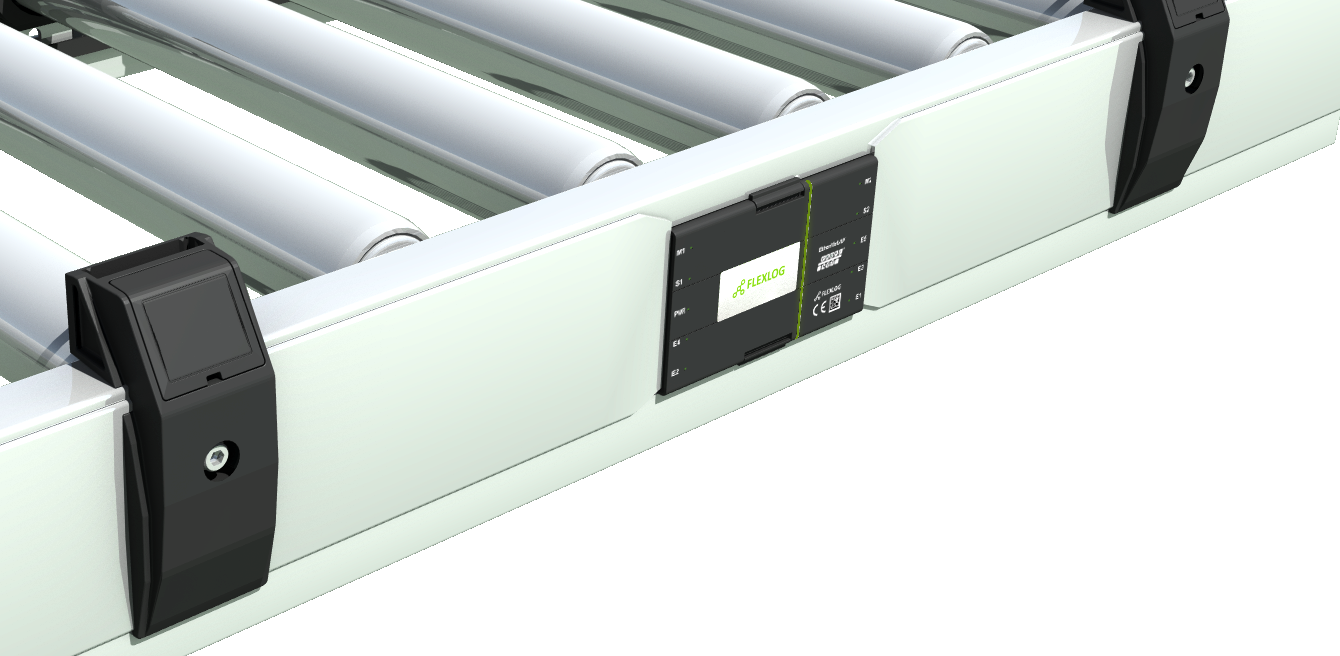

Steuerung durch unsere flexbox

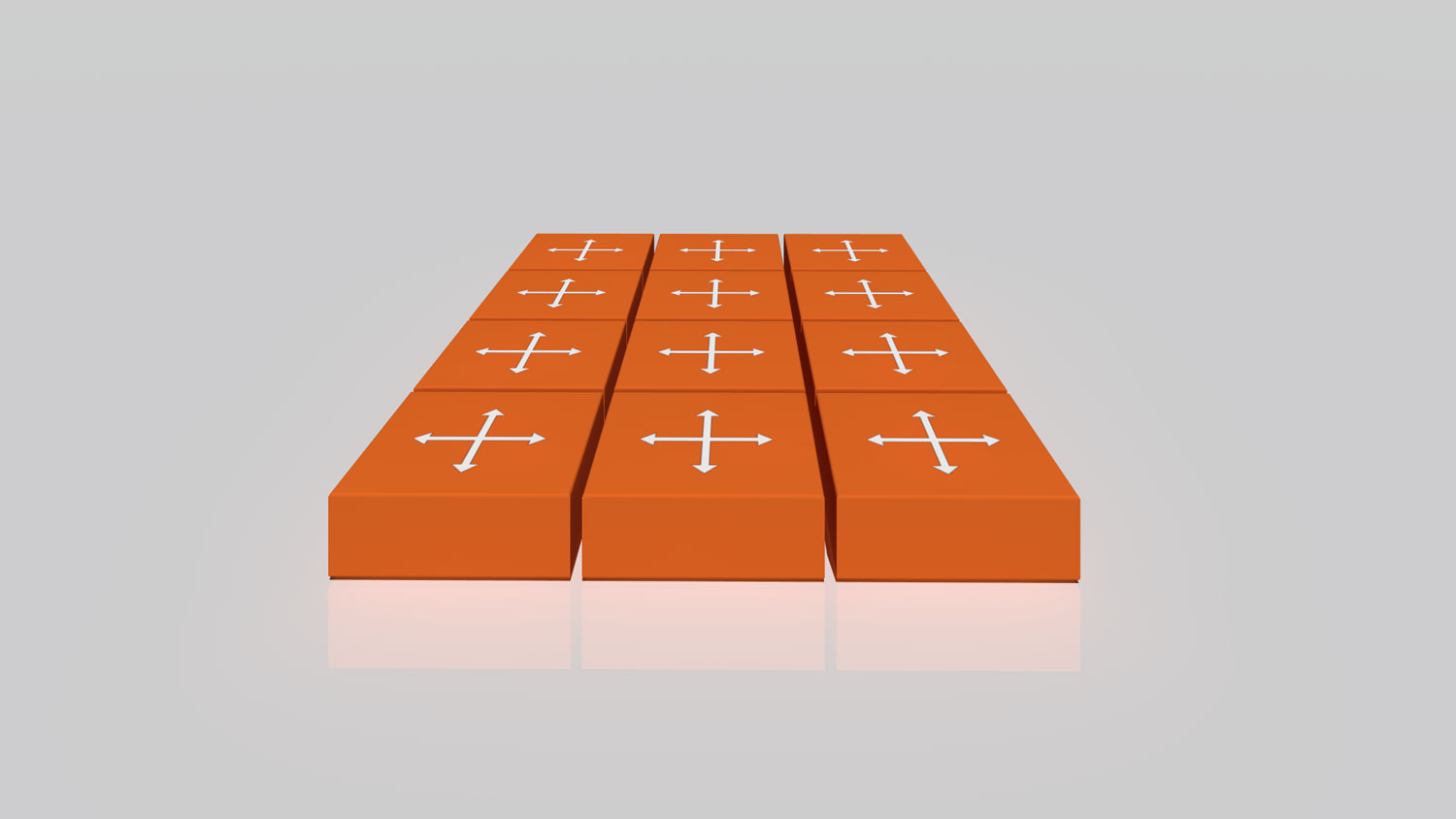

Jedes Modul wird mit einer unserer flexboxen ausgestattet. Durch die verschiedenen Varianten können wir einen Flexförderer zusammenstellen, der genau auf die Anforderungen Ihrer Förderanlage passt, von der Steuerung einfacher Logiken, über SPS bis hin zur vollflexiblen dezentralen Steuerung.

Vollständig dezentral gesteuerter Sorter

Basierend auf unserer FlexTechnologie entstand im Rahmen eines Forschungsprojekts am Institut für Fördertechnik und Logistiksysteme (IFL) des Karlsruher Instituts für Technologie (KIT) der GridSorter. Unter Leitung von Prof. Dr.-Ing. Kai Furmans wurden neue Algorithmen entwickelt, die erstmals einen vollständig dezentral gesteuerten Sorter ermöglichen. Durch den modularen Aufbau und der Flexibilität des Systems ergeben sich neben den klassischen Anwendungsfeldern für Sorter ganz neue Möglichkeiten.

Vorteile und Funktionen

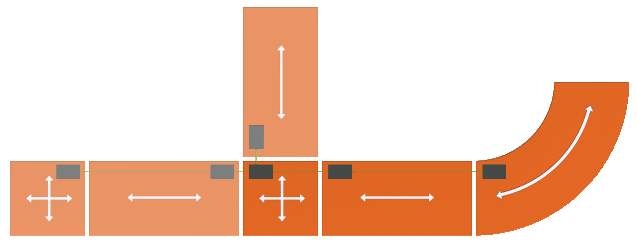

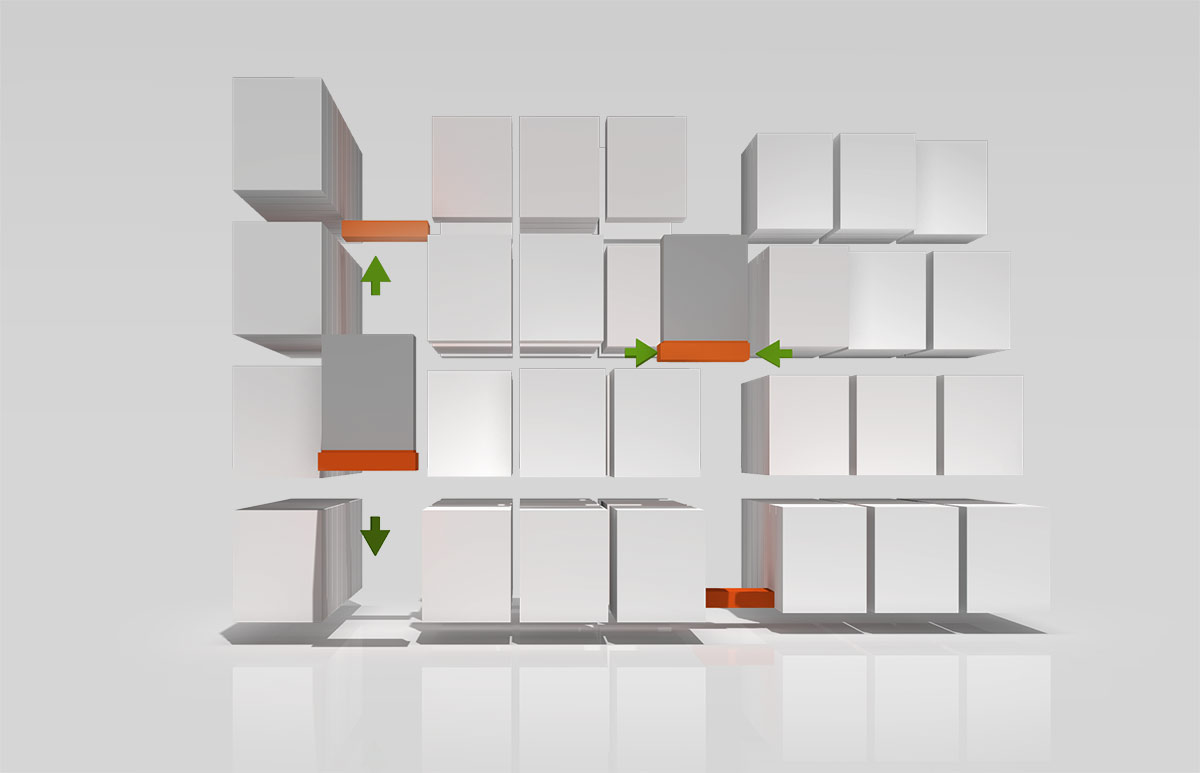

Flexible Layout Anpassungen

Der GridSorter kann flexibel an Ihre Bedürfnisse angepasst werden. Das Layout, sowie die Ein- und Ausschleusungen können je nach Bedarf verändert werden.

Platzsparend

Der GridSorter hat eine kompakte Bauweise. Bei einer Leistung von 3.000 bis 12.000 Einheiten pro Stunde weist der GridSorter ein vorteilhaftes Verhältnis von Durchsatz und Flächenbedarf aus. Je nach Layout haben die Module des Sorters unterschiedliche Auslastungen. Die Software erkennt die Auslastung einzelner Module und kann so z.B. wenig ausgelastete Module zum Puffern von Fördergütern verwenden.

3D-Shuttlesteuerung

Egal wie viele Shuttles im Lager, die 3D-Shuttlesteuerung von flexlog routet die Shuttles zuverlässig, dead- und livelockfrei, unidirektional durch das Lager – auch bei hohen Anforderungen an Durchsatz, Layout oder Flexibilität.